This guide gives you an overview of how to create logistic labels and also Serial Shipping Container Codes (SSCCs), which can be used within them, or for Electronic Data Interchange.

Using logistics labels to track pallets and other logistic units is an effective and essential part of supply chain management. Within the label, the SSCC is a unique serial number that is used to identify each individual pallet. GS1 logistics labels enable you to present information in a standard format that is recognised internationally. It uses GS1-128 barcodes to represent the SSCC for a pallet as well as certain types of information about the contents of a logistics unit.

These labels can also be used on any units that are transported between companies. For example, drums of chemicals, rolls of fabric or paper, pallets of raw materials, part pallets, or individual traded units.

Benefits

The SSCC provides a single way of uniquely identifying logistics units to make it simpler to track and trace products through the supply chain. You can also use GS1 standards to provide information about the contents of each logistics unit, which can be used in any trade and industry sector. The benefits of using SSCCs and the GS1 logistics label include:

- One label that’s used throughout the supply chain

- Improved control procedures in warehousing and distribution

- Unique identification for standard and non-standard pallets

- A consistent link with electronic data interchange (EDI) business messages

- Minimised labelling costs through the use of an international standard

- Automation and efficient handling of transport units and their contents

- Increased speed of processing deliveries

- Improved matching of deliveries against invoices

Creating the SSCC

The SSCC provides a unique identifier for each logistics unit. The SSCC is sometimes called the license plate. It contains no information about the logistics unit’s contents, but provides a link to systems where the information is held.

The SSCC is an 18-digit number and contains your GS1 Company Prefix. The company assigning the SSCC is responsible for ensuring its uniqueness. Each one can be reassigned one year after it was created and last used in communications.

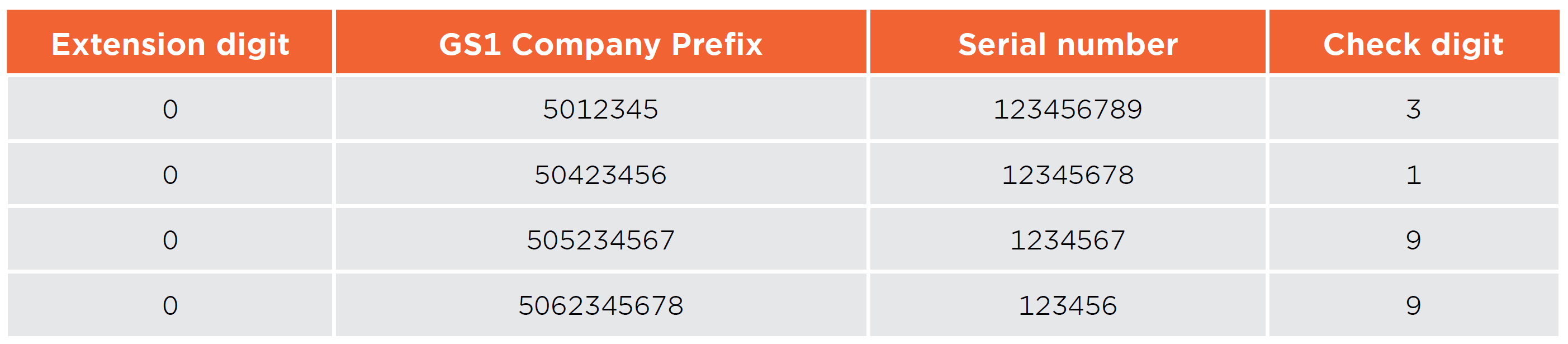

Depending on the length of your company prefix, the 18 digits are structured as follows:

Extension digit - this can be any value between 0 and 9 and allows you to create more SSCCs.

GS1 Company Prefix Number – this is allocated to you when you join GS1 UK and available in My Numberbank when you login.

Serial number – this number is between six and nine digits in length, depending on the length of your GS1 company prefix, and is allocated by the company identifying the pallet. Each individual pallet requires a different serial number.

Check digit – a calculation over the previous 17 digits. The calculation is the same as used for other GS1 identifiers, such as GTINs and GLNs. The check digit calculator can be found in the members’ area in the Tools & Resources menu when you login.

Please note that the SSCC should be used as an 18-digit number within companies’ computer systems.

Using SSCCs

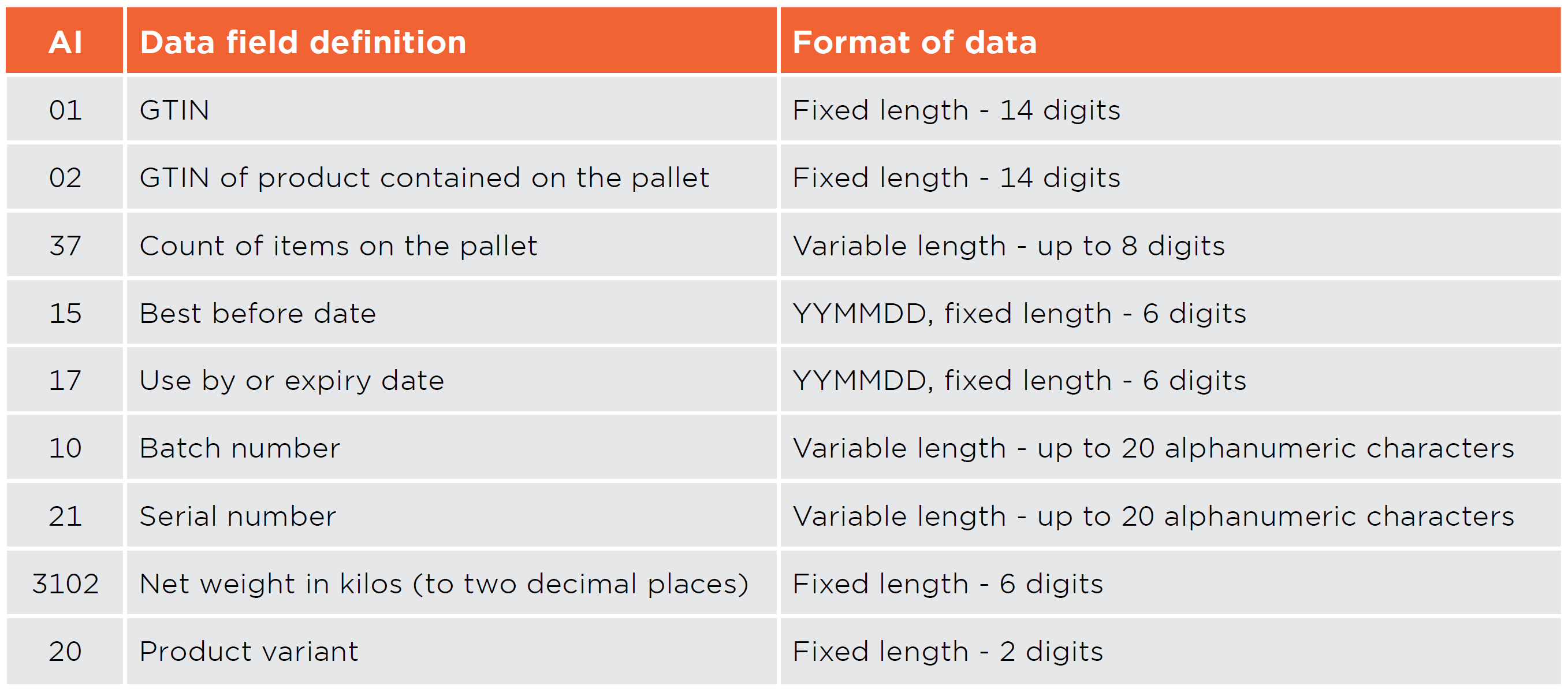

The SSCC can only be shown in a GS1-128 barcode and the application identifier (AI) 00 always denotes the SSCC. AIs can be two, three or four digit numbers that specify the data that follows them in a GS1-128 barcode – these they are agreed internationally.

Details of the contents of a logistics unit, such as the GTINs of the products on the pallet; their quantity, batch number, and expiry date, can also be shown in extra GS1-128 barcodes. Like the SSCC the different types of information is defined using AIs that are recognised and used in the same way by all companies within the global supply chain.

Wherever possible, different sets of information is joined together (concatenated) in one symbol, this ensures the most effective use of the space available.

The size of GS1-128 barcodes varies according to the amount of information shown in each barcode and the width of the bars and spaces. The width of the narrowest bars and spaces, known as the x-dimension, can vary from 0.495 mm to 1.016 mm and the height of the bars must be at least 32 mm. The maximum width of the symbol is 165 mm.

Companies using SSCCs to identify their logistics units can send details of each logistics unit to their trading partners before it arrives. These Electronic Data Interchange (EDI) business messages can be processed automatically, so when the logistics units arrive, the barcodes on the labels can be scanned and the SSCC for each pallet can be matched to the information sent in advance.

The EDI standards promoted by GS1 UK – EANCOM and GS1 XML (Extensible Markup Language) – use SSCCs, GTINs and GLNs to simplify the automation of business messaging.

The despatch advice message provides details of each delivery and uses SSCCs to identify each logistics unit. This electronic message also includes information about the contents of each unit, using GTINs to identify each product line, and GLNs to identify the trading partner and the relevant addresses.

The GS1 System provides over 200 application identifiers, some for very specialised applications. The most commonly used ones are shown below:

Please note: It is not possible to provide information about mixed or pick pallets by using AIs with GS1-128 barcodes, as an AI can only be used once on any label.

There are rules about how AIs can be used together. Some must always be used with other specific AIs, such as best before dates with GTINs.

Further information and the full list of AIs can be found in the GS1 General Specifications, which is available here.

The format of the GS1 logistics label

Label size

Most companies use an A5 label (148 mm x 210 mm) so that extra information may be included. Any label may be used as required – the GS1 General Specifications do not specify a standard size.

Label location

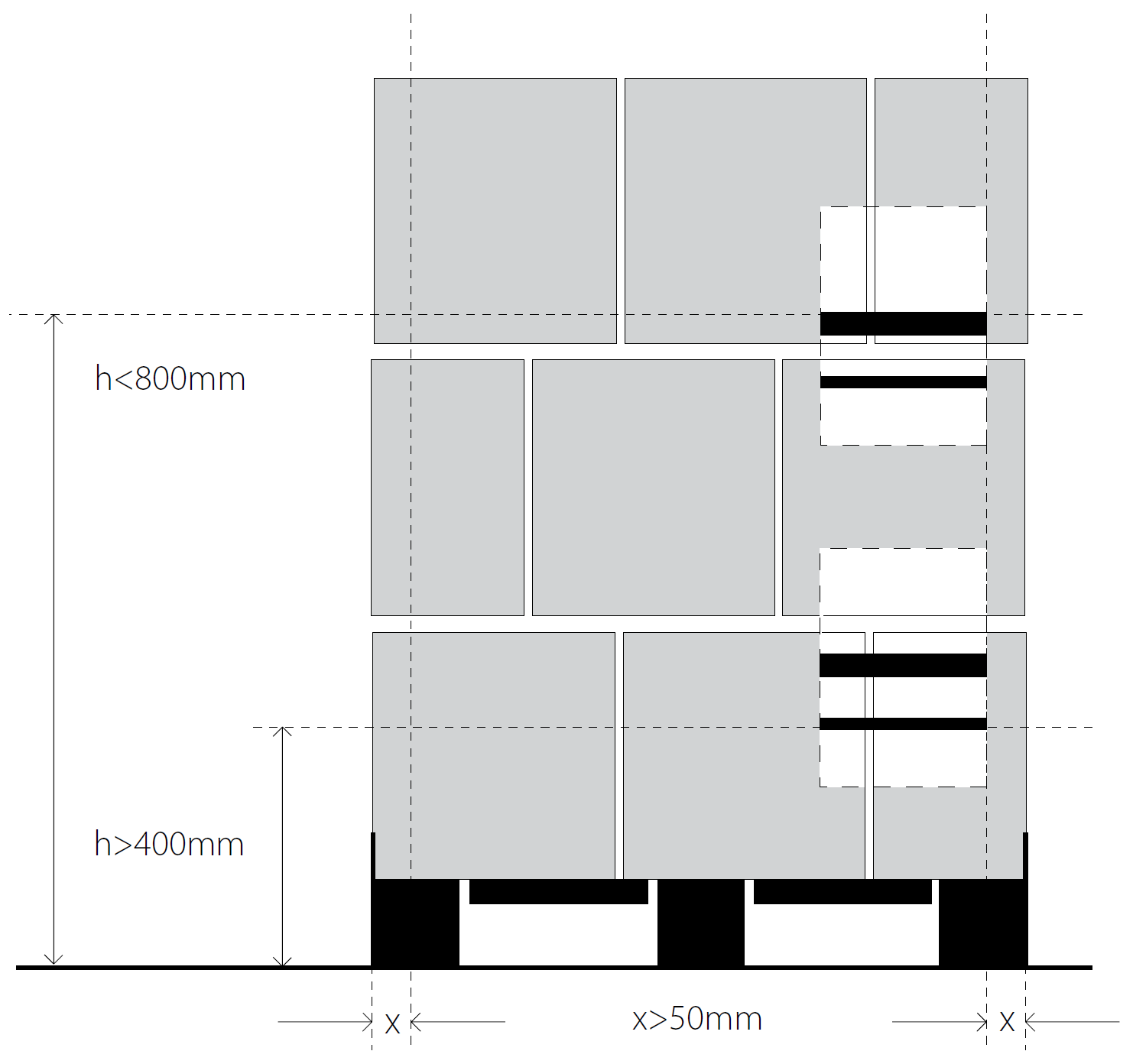

The logistics label can be used on any unit although, it is usually used on a pallet. Two labels should be attached to adjacent sides; one short side and the other on the long right hand side.

For units taller than 1,000 mm, place the label so that the barcodes are no higher than 800 mm and no lower than 400 mm above the floor.

For units lower than 1,000 mm, place the label as high as possible but make sure that the barcodes are no higher than 800 mm and no lower than 32 mm from the base of the unit.

The edge of a barcode (including the light margins) should also be no closer than 50 mm to a vertical edge of the logistics unit.

Layout

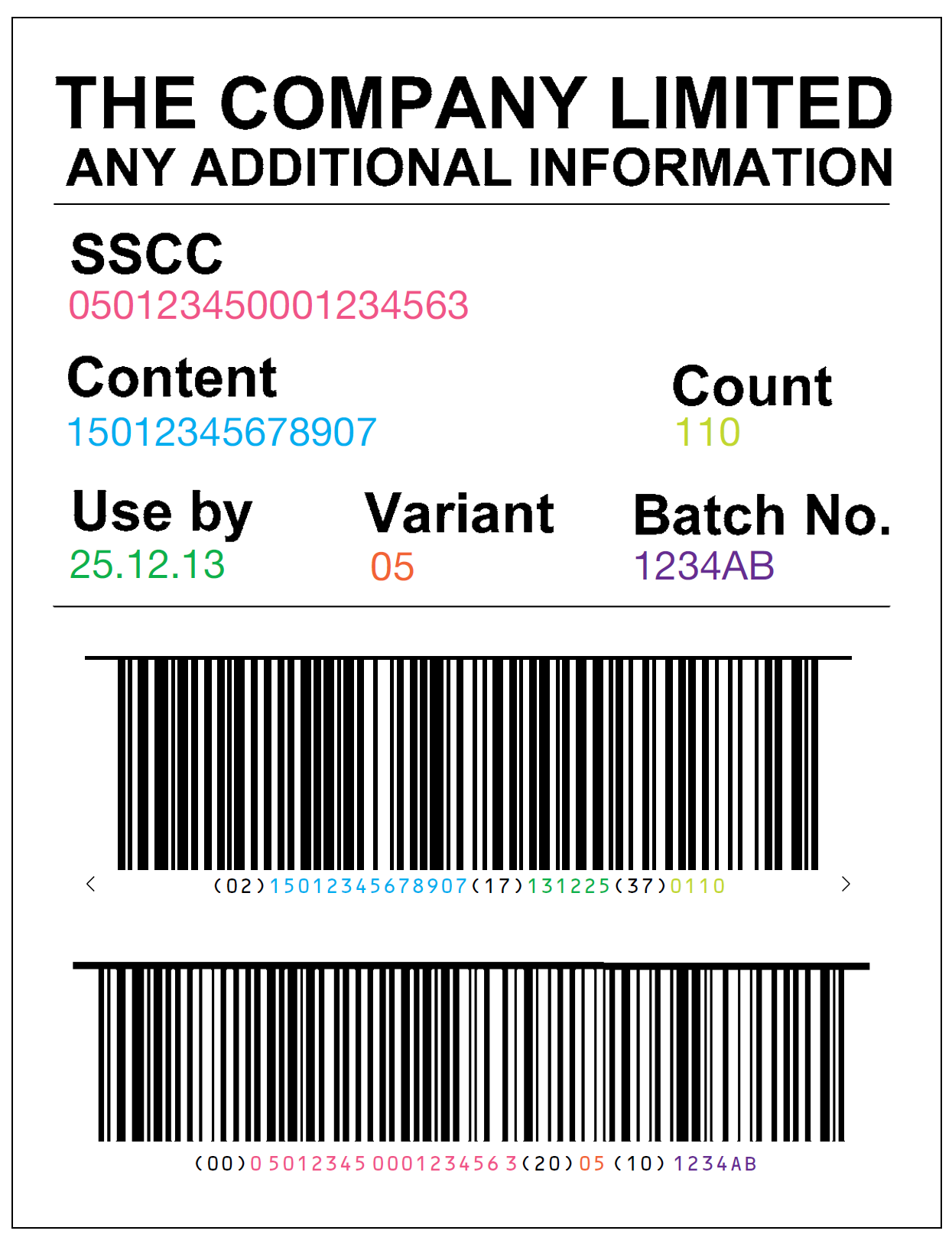

The label has three sections that allow you to provide information about the logistics unit as well as data that is defined by the GS1 System.

- Top section - company name, logo or any other information.

- Middle section - the SSCC for the logistics unit and any extra information that may be defined using the AI standards. This is shown in a human readable form.

- Lower section - GS1-128 barcodes with the encoded data shown beneath each barcode. The SSCC should always be shown in the lowest barcode on the label.

There is no limit to the number of GS1-128 barcodes that can be used on a GS1 logistics label.